If hydrogen, marked by the symbol H2, takes off as a viable alternative energy source – as to which read more below – shipping will be revolutionised, again, but faster than when it transition to LNG – liquified natural gas – 60 years ago, according to industry sources.

In May 2021, Reuters reported Tiago Bras, of Norwegian marine technology developer Hoglund, stating: “The industry is more flexible to change and should be a faster transition.”

Like LNG, hydrogen needs to be stored in hyper-cold temperatures, 100 degrees Celsius colder than LNG, at minus 253ºC – only 20 degrees above absolute zero – without pipes nor tanks cracking.

Higher strength steel, new welding technology, enhanced insulation, compressed versus liquid are all being considered by established shipping yards open-minded about hydrogen’s feasible future.

The course is being set for the most dramatic disruption to the global-energy trade since the 1970s and the rise of OPEC – the Organisation of the Petroleum Exporting Countries – according to Wood Mackenzie’s October 2021 report.

Based on assumptions that electrification is at the heart of the changing energy mix, Wood Mackenzie’s report predicts seaborne trade of oil, gas and coal will slow down from 4 % to 1 % per annum, followed by total collapse of oil and coal, compared with low-carbon hydrogen accounting for one-third of seaborne trade in a net-zero 2050 world, “turning the energy-trade world order on its head”, with immense potential as a long-duration energy storage medium, the holy grail of clean energy.

Credit The Asahi Shimbun & Taiki Koide

Japan’s Kawasaki Heavy Industries has built the world’s first hydrogen tanker, Suiso Frontier, due to make her maiden voyage from Australia to Japan between October 2021 and March 2022 with a cargo of liquified hydrogen made from brown coal.

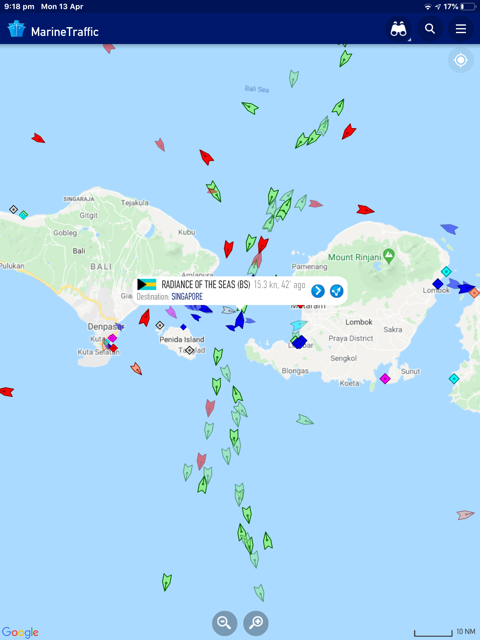

According to Marine Traffic, Suiso Frontier is currently underway from Kobe to Komantsushima.

Fremantle Shipping News will keep you abreast of progress.

The company aims to go commercial by 2030, driven by former Prime Minster Shinzo Abe’s ambition for Japan to be the first country in the world to realise a hydrogen-based society.

Norway’s Wilhelmsen Group also has plans to transport H2 in containers on their hallmark RO-ROs by 2024.

All of this and much much more can be expected if hydrogen is to become the energy source of tomorrow.

PLEASE HELP US TO GROW FREMANTLE SHIPPING NEWS

FSN is a reader-supported, volunteer-assisted online magazine all about Fremantle. Thanks for helping to keep FSN keeping on!

Back to H2 production, producing commercial volumes of hydrogen for fossil-fuel intense users such as cement, steel, transport, ships, aviation, trucks and chemicals is the key.

Currently, fertiliser and chemical refineries absorb the 100 million tonnes produced globally.

The following is a simplified overview of the benefits of hydrogen and the different ways it’s produced.

Hydrogen does not emit carbon when combusted. It has a high energy density thus providing the intense heat essential for cement and steel production, and it can be converted into a synthetic fuel for aviation, trucking and shipping.

‘Grey’ hydrogen converts natural gas to CO2, and accounts for 71 per cent of hydrogen produced, followed by ‘brown’ which is extracted from coal. ‘Blue’ hydrogen is a lower-carbon, lower cost alternative to ‘green’, which is the cleanest, produced from water, but currently the most expensive requiring vast renewable resources – which Australia and the Middle East have.

Shipping storage for hydrogen is challenge number one, fuelling the ships a close second, demonstrated with the world’s first liquid hydrogen vessel – yet to be proven – Japan’s Suiso Frontier.

* This article was written by PA Sinclair, our Shipping Correspondent

** Don’t forget to SUBSCRIBE to receive your free copy of The Weekly Edition of the Shipping News each Friday!